Our products: vertical turbine pump, vertical wet pit pump, vertical oil sump pump, vertical condensation pump, right Angle gearbox

DATE:2024/2/4 16:20:00

Visits:

API610 VS1/VS6 Series Vertical Suspension Turbine Pumps

Executive Standards:GB/T 3215-2019、ISO13709

Reference Standard:API610-2010

Maximum flow: 8,800 m³/hr (39,600 gpm)

Maximum head: 456 m (1500 ft)

Maximum temperature: 200°C (388°F)

Discharge diameter (mm): 100-1000mm

Working pressure: P=11MPa

Operating temperature: T=-60℃~+150℃(Inner shell segmental type)

Operating temperature:T=-196℃~+150℃(Inner shell deflector shell type)

Applications: It can convey a variety of clean, polluted, low or high temperature, chemically neutral or corrosive liquids. It is mainly used in refineries, petrochemical industry, cryogenic engineering, pipeline pressure regulation or offshore platforms, condensate extraction in the energy industry, liquefied gas engineering, etc.

The VS1/VS6 series vertical suspension pumps comply with API610 11th Edition and ISO13709 "Centrifugal Pumps for the Petroleum, Heavy Chemical and Gas Industries" standards.

VS1 is a vertical suspension type, a single-layer shell, and its discharge pipe passes through the riser pump; VS6 is a vertical suspended and double-layer casing pump; Suitable for all occasions.

This series of pumps is a new generation of low-temperature resistant and anti-cavitation pumps independently developed by our company to absorb foreign advanced technology. The impeller is a single-suction structure, radial or guide vane with a guide shell. The first-stage impeller has excellent cavitation resistance. The pump is equipped with a balance drum device to balance the axial force, and the residual axial force is borne by the matched bearings.

This series of pumps has been carefully considered in the hydraulic design, rotor rigidity, shaft connection mode, guide bearing structure, mechanical seal components, seal flushing and other auxiliary systems, and solves the use and installation defects of in-service pumps in the market.

VS1/VS6 500-72×8-A-D

VS1:API610 (ISO13709):Single-shell vertical suspension pump

VS6:API610 (ISO13709):Double-shell vertical suspension pump

500:FLOW(m³/h)

72: HEAD(m)

8:Impeller progression

A:Product classification code

A—Multi-stage radius guide vane structure

B—Multi-level space diversion shell structure

C—Single-stage, two-stage high-flow inclined flow pump structure

D:Structural code

D—First-stage double-suction structure (single suction is not indicated) K—Open impeller structure

J—The first stage impeller sinking structure

★ Petrochemical ★ Refineries ★ Cryogenic engineering

★ Oilfield gathering and transportation ★ Offshore platforms

★ Petrochemical Industry Engineering ★ Coal processing industry

★ Cold oil transportation engineering ★ Environmental engineering

★ Line pressurization ★ Offshore oil ★ Gas separation device

★ Vapor-liquid pumping in the energy industry ★ Light hydrocarbons

★ Liquefied gas engineering ★ Low cavitation applications

Ø Double-shell construction

Ø It is rigid enough to withstand the inlet pressure and the pressure difference between the inside and outside of the cylinder

Ø The installation depth is varied to meet the requirements of the NPSH of the device

Ø Isobaric design for inlet and outlet

Ø The inlet and outlet flanges are positioned in various positions to meet the requirements of different pipeline configurations

Ø The outer casing can be removed and used as a tank or pipeline pump

Ø The inlet and outlet ends adopt the method of integral casting and inlet and outlet flange welding

Ø Minimize the axial length of the pump

Ø Easy maintenance

Ø There are various types of inlet and outlet flanges to meet the requirements of different sealing types and pressures

Ø Replaceable pump body and impeller seal rings

Ø The wear-resistant ring is fixed with interference fit and seam screws

Ø Precision casting and polishing to ensure the design effect

Ø The CFD design guarantees maximum hydraulic efficiency

Ø The first stage impeller has excellent low cavitation performance

Ø Curves without humps

Ø Closed impellers are standard

Ø There is a clearance in the axial direction of the impeller positioning, and the temperature change reduces the deformation of the shaft

Ø There are two types of runner guide vanes and radial guide vanes

Ø The guide vane type is selected according to the working conditions

Ø The radial guide vane has a short axial distance

Ø The runner type guide vane has a small radial size

Ø Fully welded, casing connection

Ø Seamless steel tubing is standard

Ø A wide range of materials are available

Ø The cavity meets API610 and API682 standards

Ø The installation space is large, and various types of mechanical seals can be configured to meet the requirements of various process conditions

Ø Cartridge mechanical seal is standard construction

Ø It can be equipped with various types of mechanical seals such as single and double ends

Ø It can be equipped with dry gas mechanical seals according to the medium situation and the owner's requirements

Ø Various sealing flushing and cooling schemes can be configured

Ø Easy to disassemble

Ø Balance plate device is used to balance the axial force.

Ø Achieve throttling, reduce volume loss, and ensure performance parameters.

Ø Reduce the pressure of the sealing chamber (when conveying saturated or near-saturated media, an external pipe can be used to increase the pressure of the sealing chamber)

Ø It is not easy to lock during operation and is easy to maintain

Ø Graphite/PTFE bearings are standard, other configurations are also available

Ø Self-lubricating of the pumped medium

Ø Bearings are positioned individually

Ø Mounting according to API610 standard, optimized bearing spacing

Ø Configured as standard for large inclination mated angular contact ball bearings

Ø Equipped with machined steel cage

Ø Thin oil lubrication as standard

Ø The large oil storage chamber of the bearing box is equipped with an independent internal circulation automatic lubrication system, which can not only effectively lubricate the bearing, but also make the oil temperature constant to ensure the long-life operation of the bearing.

Ø When the temperature of the conveying medium is high, the cooling device can be used to reduce the temperature of the oil chamber.

Ø Large capacity design of oil chamber, large oil storage capacity.

Ø Constant oil cup compensates for lubricating oil online, and oil level gauge detects oil level in real time.

Ø The bearing parts can be disassembled and assembled as a whole, and the maintenance is convenient

Ø Integral shaft machining, low-stress treatment

Ø The minimum deflection of the shaft at the mechanical seal is lower than the API 610 standard value, thus increasing the service life of the mechanical seal

Ø Reasonable coupling method ensures the concentricity of the shaft at the special insertion depth

Ø Extended diaphragm coupling is standard

Ø Other types of couplings can also be selected

Ø The key connection is fixed

Ø ISO1940-1 G2.5 Balanced Rating

Ø Complete welding

Ø The observation hole can also be used as a maintenance hole, and the bearing parts, sealing parts and balance parts can be repaired without disassembling the motor and motor support

Ø API material options from S-4 to D-2

Ø Meets NACE and low temperature material standards

Ø The use of corrosion-resistant coatings can improve the service life of critical parts

Ø Non-metallic wear-resistant parts, which can improve the use environment and improve performance parameters

Ø Strong corrosive medium, Monel, Hastelloy, duplex stainless steel and other materials can be used

Ø Other materials can be selected according to the working conditions

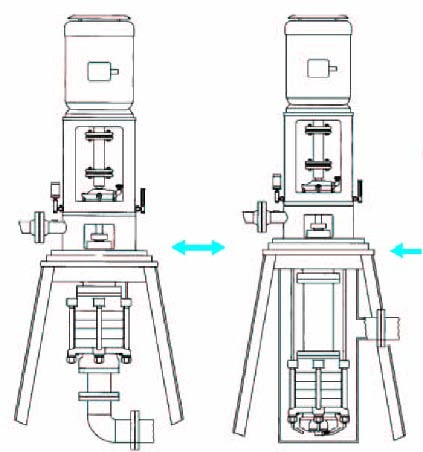

Standard structure

Ø Suitable for most applications of vertical bobbin pumps;

Ø The position of the suction pipe and the discharge pipe is in the upper part of the mounting base;

Ø Suction pipe and discharge pipe are arranged at 180° to each other;

Ø Can be used as a standard line pump;

Ø Housing only withstands inlet pressure;

Ø The base can be selected as welded or flat according to the installation space and the owner's requirements;

Ø The pump is equipped with a housing drain pipe for easy maintenance.

Tank pump and submersible pump structure

Ø Can be installed on the tank as a standard tank pump;

Ø Can be installed on the intermediate tank as a

booster pump;

Ø Selectable insertion depth for use as a standard

submersible pump;

Ø The position of the discharge pipe can be installed on the upper part of the flange;

Ø No need to install the shell, flexible movement;

Ø The installation flange can be set according to the

owner's requirements;

The minimum opening diameter and minimum liquid level of the tank or intermediate tank are set by the manufacturing plant.

Flange connection

Ø Flange connection structure is adopted according to the installation space requirements;

Ø The location of the discharge pipe is in the upper part of the mounting flange;

Ø The direction of the discharge pipe can be set freely in the horizontal direction;

Ø Suction pipe connection can be selected flange direct connection or container connection;

Ø The installation foundation adopts section steel welded frame or civil foundation;

Ø  The installation dimensions are agreed upon by the manufacturer and the owner.

The installation dimensions are agreed upon by the manufacturer and the owner.

Copyright © 2002-2022 Hunan machinery manufacturing co., LTD. All Rights Reserved.

+8618507312158

WeChat Qr Code